how to become an electrician apprentice

Dan has been a licensed journey-level electrician for some 17 years. He has extensive experience in most areas of the electrical trade.

It takes more than a conduit bender to make an electrician, although it is a start.

Wilderness

While someone just becoming an electrician most likely has a severely limited budget, the set of electrician's hand tools is not the place to cut cost by buying cheap tools. Cheap tools will not last and are much more difficult to use; a simple rubber handle on a screwdriver can make a large difference if you have to use it all day. Make sure that high-quality tools fill the new electrician's tool bag.

The same basic tool may come in many different brands with many different prices, so I will recommend brands as well as the actual tool where applicable. Klein makes high-quality electrician tools, as do Knipex, Ideal and Greenlee. Milwauke, Dewalt, and Bosch make professional quality power tools.

Below I'm going to discuss some very specific recommendations, with some links to places you can look at them and buy them.

There are dozens of different styles of pliers available and the well-equipped electrician's tool bag will contain several of them.

Needle-Nose Pliers

A good set of needle-nose pliers is indispensable for the electrician. Klein and Knipex both make a very good set, with built-in wire cutters, and even a stripping hole for #12 wire, both of which are handy options. Needle-nose pliers for the electrician should always have the wire-cutter option. The Knipex set also includes crimpers for ferrules. Personally, I prefer the Klein J203-8N pliers.

Lineman's Pliers

A good heavy set of lineman's pliers will often be needed. Again, Klein makes a very good set with an optional fish-tape-pulling arrangement on the side of them: a very handy option for the electrician. The arrangement on the side is far preferable to the same type of option where the fish tape fits between the handles; it is far too easy to receive a very nasty pinch with that style.

Side-Cutting Pliers (Dikes)

Side-cutting pliers, or "dikes" are common to every electricians tool set. These are used to not only cut wire, but nails, staples, MC cable, and other items. Make sure that the jaws are specially hardened for such use, not merely intended for cutting copper or aluminum wire. Klein makes two different sets; one with red handles and one with blue handles and hardened jaws. Knipex also makes a good set of side-cutting pliers. These pliers should be in the 8" - 10" length.

Slip-Joint Pliers

Commonly called channellock pliers (a trade name) a 8" or 10" pair of slip-joint pliers will be required. Recommended here are the Knipex Cobra 10" pliers, or even the three-piece set of 7", 10" and 12" lengths.

Wire Strippers

Although not truly pliers, a pair of wire strippers is a necessary item in the electricians tool belt. Wire strippers are available for Romex wire, but far more common are simple strippers for #10 and smaller solid (not stranded) wire. Ability to strip #8 and #6 wire is a plus, where available. Recommended are either Ideal or Klein strippers; Ideal is usually a little cheaper, though Klein is more comfortable to use. Recommended is the Klein 11055 wire stripper.

Don't buy the automatic style of wire stripper, just a simple pair of wire strippers for several sizes of solid wire. GB offers a set of wire strippers with a built-in voltage tester, but they cost considerably more. As wire strippers are considered a "throw-away" tool (they wear out frequently) the extra cost really isn't worth it.

Razor Knife

In addition to wire strippers, get a razor knife. One of its many uses is cutting the sheath on the NMC wire used in residential. Using wire strippers for this will sooner or later damage a wire.

Included in this section are screwdrivers, nut drivers, and similar tightening tools for the electrician.

Screwdrivers

A top quality set of screwdrivers will be in every electrician's tool bag. You need to include a cabinet tip flat blade, a larger flat blade, a #2 Phillips, a #1 Phillips, and a #2 square tip. Klein is recommended, but Ideal also makes an acceptable screwdriver set.

Nut Drivers

You will want a good set of nut drivers, from 1/4" to at least 7/16". I recommend Klein, in the medium length shaft. The Klein set with long hollow shafts is useful in some circumstances, but not worth the extra trouble of carrying the long handles in the electrician's tool belt.

Allen Wrenches (Hex Keys)

Allen wrenches are a must. Electricians typically prefer sets of Allen wrenches, such as those Klein makes; they use both large and small sets, in SAE sizes. Very occasionally it would be nice to have individual allen wrenches, but it is not worth the extra trouble and cost, and individual wrenches are often forgotten and lost.

Socket Set

An electrician will use a socket set, unless he/she is a strictly residential electrician. This is not a high-use item, nor is it used to tighten to extremes. Deep sockets are more valuable than shallow, and both 1/4" and 3/8" ratchets are useful. A Craftsman brand set or the equivalent is sufficient here, but be sure it has a good selection of deep sockets.

Adjustable wrench

A couple of adjustable wrenches, of perhaps 8" and 10" length, will be found in the electrician's tool set. Again, absolutely top quality is not needed as they will get light duty only; brands like Craftsman are quite adequate.

Pipe Wrench

Sometimes a pipe wrench is invaluable; Ridgid makes a good pipe wrench in about the 10" size that will work well. A second wrench of the same size is advisable for working with rigid conduit.

Conduit Reamer

Although not strictly a screwdriver, a conduit-reaming tool is necessary for any electrician running conduit. Klein is recommended with its dedicated tool. Reamers are available for square-shank screwdrivers, but they do not work nearly as well, as the long screwdriver blade prevents the reamer tool from entering a conduit that has a bend near the end of the conduit.

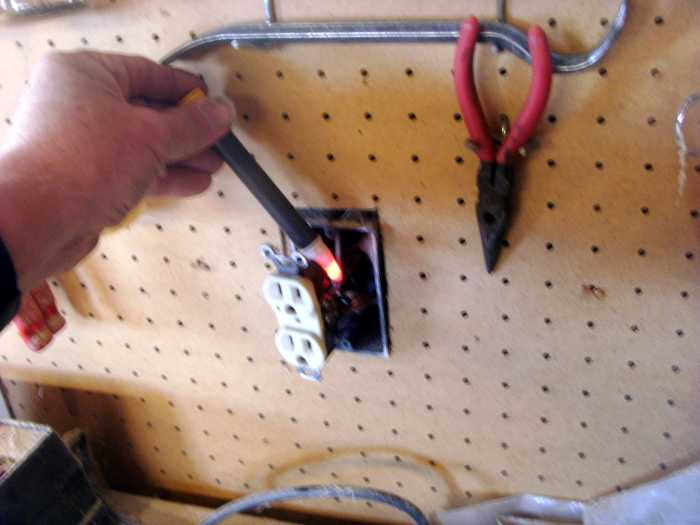

Using a tick tester, or non-contact voltage detector. Find hot wires before cutting or stripping them.

Wilderness

Voltmeter in use. Know what voltage you will be dealing with, and whether it is hot.

Wilderness

Electrical Meters and Testers

Every electrician's tool bag needs to include several meters and testers.

Multimeter

You need a multimeter capable of reading up to 600 volts; it should also be able to detect continuity. A clamp-on style of multimeter with amperage capability is preferable. Fluke is the preferred brand, although cheaper brands are available and will be adequate for the apprentice who is just becoming an electrician. The Fluke 322 AC Clamp Meter is a good choice for the beginning electrician.

Tick Tester (Non-Contact Voltage Detector)

Every electrician should be equipped with a non-contact tester ("tick tester"), and many have a spare tester in the truck as well as one in their pocket. Testers that use ordinary AAA batteries are preferable. Fluke again makes a good tester.

Plug Tester

A plug tester with a built-in GFI tester is necessary and fairly inexpensive. Nearly any brand will work just fine here.

Specialized Voltage Tester

These are simple testers that will test for the presence of various specific voltages as well as continuity. They make an excellent replacement for a true multimeter, and most electricians will have one in their tool bag whether they have a multimeter or not. If funds are available, either the Fluke T+PRO Tester or the Klein ET200 is a good addition to the tool kit.

Drill Kit

A good cordless drill kit is a necessity. As cordless tools have increased in popularity, the sawzall has become almost a requirement for an electrician, although an ordinary hacksaw will still suffice.

Recommended drill kits are either the Milwaukee or Dewalt drill and sawzall kits. The kit's battery should produce at least 18 volts, and the kit should contain at least two batteries, though three are very handy. A one-battery charger is sufficient for most people, although dual battery chargers are available. If possible, get a kit with a flashlight.

The new lithium batteries are a major plus, and far superior to the older nicad batteries if you have the money. Purchased separately they are expensive and require a special charger, so they should be purchased with the kit if at all possible.

Avoid cheaper brands for drill kits if possible, as their lifespan is limited, their batteries are generally lower quality, and the charge doesn't last as long. Cheaper kits such as Ryobi and Makita are an option, if you keep this limitation in mind, but the new electrician needs to realize that they will need replacement in only a year or so.

The newer cordless impact drivers are a very, very nice addition to the tool bag, and again should be considered if funding is available. If possible, the drill itself should be a hammer drill, as the electrician is often required to drill masonry or concrete.

Conduit Benders

If an electrician is expecting to work in the commercial or industrial field, they will need conduit benders in ½" and ¾" sizes and perhaps 1" as well. These are not common tools found in every household. It may take some time to learn to bend conduit properly, but it is time well spent.

Level

A good torpedo level is an absolute necessity; don't get the cheapest one. Strong earth magnets to hold the level onto conduit or other metal surfaces will delay the occasion when you drop the level and have to replace it. A plastic case will loosen over time and result in poor readings: make sure your level has a metal case. A level with a 30º vial can be very useful, so consider paying a few more dollars for that feature. Checkpoint brand is recommended, and the 300PL is a reasonable choice in that brand.

Measuring Tape

A good quality measuring tape in either a 25' or 30' length is mandatory. Get a tape measure at least one inch wide: less width means less strength, which means the tape will not extend as far out without bending (standout length). Stanley makes a very good tape measure (their "fat max" series) that I recommend

Tool Belt

You can see that an electrician will need a tool belt, to keep some of the items above. There are many styles of tool belt for different trades. An electrician's tool belt should have several pockets on one side for small parts and supplies, and pockets on the other side for hand tools. It should include a place to hang electrical tape and a loop for a hammer.

Too many pockets, however, can become a hindrance. The more tools and parts are added, the heavier the belt and the more work it is to wear it all day. Many electricians use a tool belt with only a couple of pockets for parts, though three are four pockets can be handy to keep parts from getting mixed up. Several pockets will be needed for hand tools, with loops on both the inside and outside for pliers. For specialty work, such as installing large numbers of switches or plugs, a small sheath for just a screwdriver and a pair of pliers can be very handy, to pare down the weight on days when the electrician knows they will need only a few hand tools.

Consider a set of suspenders for the belt, as they distribute the weight to the shoulders and make carrying the belt an easier job. They are spendy, however, and can wait if necessary.

Whether your tool belt is leather or nylon is a matter of personal taste. Do make sure, however, that the belt buckle is adjustable and long enough to accommodate winter clothing. A tool belt constructed with heavy-duty stitching and rivets should last for years. An electrician's tool belt should be available at your local home improvement store such as Home Depot, and they are widely available online, including at Amazon.

Tool Bag

A tool bag is also quite desirable, to transport tools into the job site each morning and remove them in the evening. Theft of tools is quite common at job sites during night hours and most electricians won't risk losing their precious hand tools. The electrician's tool bag is one place, however, where some money can be saved: many use nothing more elaborate than a five-gallon bucket, although a nylon tool bag has the advantage of pockets inside and/or outside for smaller tools.

A whole host of tools are useful to the electrician, but the tools above are the primary tools every electrician needs. Some suggestions for the future might include a tubing cutter of the type plumbers use as it is useful for removing conduit from around wire without harming the wire. Ratcheting cable cutters are nice but very spendy (nearly as much as the required drill kit). More and more work is being done with MC cable, so cutters and strippers for it are useful as well. A cheap calculator is nice, but most cell phones now have enough capability for most electricians. Additions to the cordless drill package such as a circular saw or a peanut grinder can be handy, but can be added later and are of only limited use in any case. Most electricians will eventually own a 100' roll-type measuring tape.

The list can, and will, go on and on. You will need pencils and sharpies (indelible markers), some kind of knife (razor knife, box cutter or large pocket knife), and other common household items. As you progress towards the journeyman level, you will need more exotic tools unfortunately often more expensive ones. But the tools listed above should start the apprentice just becoming an electrician down the road they need to follow, well stocked with electrician's hand tools.

This article is accurate and true to the best of the author's knowledge. Content is for informational or entertainment purposes only and does not substitute for personal counsel or professional advice in business, financial, legal, or technical matters.

Questions & Answers

Question: My son has put cobra grips on his Christmas list. Is a set of 3 best or would some of them not get used?

Answer: They definitely have different uses, and if he does a lot of work with pliers he will certainly have a use for all three. I find the larger pair to be the least used, but they can be invaluable when needed and it is quite possible that your son would find the largest pair to be the most used. It just depends on what he is using them for. If it is in the budget I would suggest the set of three.

© 2010 Dan Harmon

Boris Arriola on September 23, 2019:

Thanks, Dan Harmon. This is a complete list of tools for an electrician. You have categorized all items which made the list easy to find the tools that needed tool.

Dan Harmon (author) from Boise, Idaho on July 29, 2016:

That's correct, Sean - I do not recommend insulated tools except in special circumstances. They are considerably more expensive, and to maintain their insulation value must not have even a small nick on the surface of that insulation.

As there is seldom a need for working "hot" (though we all do it), better to use an effective tester than trying to maintain insulated tools through the knocks of everyday use.

Nor is it unheard of to work with uninsulated tools: I have never seen an electrician on the job (under 500 volts) with a toolbelt of insulated tools. They just aren't that useful, and I will go so far as to say that no new apprentice (the target of this article) has any business working hot on anything but perhaps 120 volts.

Dan Harmon (author) from Boise, Idaho on July 29, 2016:

In seventeen years of using the tool almost daily I have never had a false negative. That is, it has never reported no voltage but the line is hot. I HAVE had it report a voltage when there was none, but I can live with that happening very occasionally.

Sean on July 18, 2016:

I should have specified that I was referring to the adverts placed for uninsulated tools of the same brand mentioned after each paragraph. This should be monitored as it is misleading and seems as if you are endorsing these tools.

Sean

Sean on July 18, 2016:

The information here just seems plain irresponsible for those not in the know. Volt stick aren't reliable enough to trust that you're not going to get a belt and these may be good tools but not one of them seems to be insulated. Someone asked what is the need? - When you cut through a live cable during a brain fart you'll find out! Then you'll buy some insulated tools :)

Hemanta sasmal on August 02, 2015:

Thank you for give the valuable information

Dean Walsh from Birmingham, England on November 02, 2013:

Useful list - its the testing equipment which cost the money, but there are also some pretty cool products out there. Fluke are great, and have some advanced stuff.

Dan Harmon (author) from Boise, Idaho on May 24, 2013:

Brandon, it should be. Depending on the specifics of what you will be doing, there may be a few other items not included here; a punch down tool or low voltage scissors, for instance. On the whole, however, it should do well. I suggest you check with the center, and come back for specific recommendations as to type or brand.

Brandon L on May 24, 2013:

im going to career center for this and would like to know if this is a good list for me

Dan Harmon (author) from Boise, Idaho on May 02, 2013:

I don't know - those Klein strippers are the ones I use, too, and I wear out a pair a year or so. They get dull and won't cut anymore, though they DO last better than anything else I use. Maybe cutting lots of #10 and 8 solid wire is what hurts - I do that a lot as more commercial jobs require solid wire.

It's true that I usually ruin them first, though - just as you say, cut a live wire. Still, I've got a pair in the toolbox right now that are simply dull - I keep them in case I ruin the good pair and need something for a day or two until I can replace the ruined pair.

Robert Monk on May 02, 2013:

Great information in general. I have to disagree about wire strippers being a 'throw away'. My typical Klein komfort kurve wire strippers (featuring 14/2 and 12/2 romex jacket strippers, #14 and #12 wire strippers, and use the #14 jacket stripper for #10 wire stripping, threaded screw cutters, wire end looping hole, and wire cutter... what else...?) last several years. Usually, they fail when I sit on them or step on them and bend them, or I cut into a live circuit one too many times. Fortunately, I do that once/year maybe, vs. once a month like when I started in residential renovation -- and that's doing 10x the volume of work as before, too.

In my opinion, the Kleins will last at least until you screw up and lose them, step on them, or otherwise do something stupid to break them or knock them out of alignment. Well worth $40 (or $28 or whatever you can get them for).

Dan Harmon (author) from Boise, Idaho on October 24, 2012:

I don't know about Texas, but around here a journeyman's license is good for about double the money. Worth the effort to get, in other words.

I absolutely agree that a variety of marketable skills is extremely valuable in today's world. You just never know when you will be laid off or a company will fold and you will find yourself once more in the unemployment line.

Wesman Todd Shaw from Kaufman, Texas on October 24, 2012:

Oh you are very kind!

I'm not a "real electrician," but I'm pretending to be one this Fall/Winter....my brother and myself...are the ONLY two males in the extended Shaw family that aren't VERY real electricians.

I know you're the real thing...I'm just an apprentice with....lots and lots of miles on him!

I might go test for a Texas Journeyman's license soon though - I'm good at passing tests...and diversifying our marketable skills is forever a very good idea!

Dan Harmon (author) from Boise, Idaho on October 24, 2012:

Good catch, Wesman. I've seen even journeymen doing that, and I even tried it myself. For about two wires; it didn't take long to realize that damage was almost inevitable. A razor knife (box cutter) just doesn't do the damage that wire cutters will in removing Romex sheathing.

Thanks - I've modified the list to include that knife.

Wesman Todd Shaw from Kaufman, Texas on October 24, 2012:

One thing I keep running into this Fall....are the mistakes of someone who was fired.

The individual was using his set of strippers to strip off the outer insulation of Romex wire...and rather too frequently, he'd bite into the one of wires, or even break it...leaving it hanging by its own insulation.

Oh gosh....just never do that. Get a good razor blade knife to cut the outer insulation when cutting Romex into a box :)

Dan Harmon (author) from Boise, Idaho on October 23, 2012:

This would vary a great deal state to state. Child labor laws will come into effect, as will requirements for becoming an apprentice. I would think that 17 year olds should have no problem starting an apprentice program, but at 16 years it could be problematic.

The best I can offer is to check with the authorities in your state. Perhaps a building safety department, or where a builder would get a building permit - they could surely direct you to the right place.

Anonymous on October 22, 2012:

Is it possible to become an apprentice or even a pre-apprentice before the age of 18? In the future, I plan to work as a residential electrician. I want to get some college credits as well as work experience to get a head start in life. I reside in Oahu, Hawaii and want to know if there are any apprentice ships ( or pre-apprenticeships) in the near future that accepts 16-17 year olds. Thanks.

Dan Harmon (author) from Boise, Idaho on October 05, 2012:

Not sure here, apprentice. I've used two pouches, but one of them is just a tiny thing to carry strippers and screwdriver for trimming switches and plugs. Not actually a pouch at all.

I've always simply re-filled my regular pouch as jobs went from one phase to another. Won't be running pipe? Dump the conduit reamer and parts for it - refill with wire nuts and nut spinner. Or whatever the next task takes. Yes, I'll have to do that several times as I may go back to pipe the next day, but it saves buying a separate set of bags, and good ones aren't cheap. Plus, I always carry a few of the same tools - screwdrivers, channel locks, etc. - is he expecting you to double up on those, too? I don't know anyone that carries two complete sets of bags - never heard of such a thing.

Always good to hear from a new apprentice starting out - here's wishing you luck in your career!

apprentice on October 05, 2012:

hi, just wondering what a good "rough-in" pouch would consist of, as i am about to start as an apprentice electrician and my employer said i will need an electrician pouch/belt, which i have, and another pouch/belt for rough in work

Dan Harmon (author) from Boise, Idaho on June 08, 2012:

I have owned and used Dewalt, Milwaukee and Makita power tools, although the Makita brand was quite a while back. I have never used a Milwaukee tool I didn't like and in terms of longevity and power Dewalt compares favorably. Milwaukee has generally won in terms of ergonomics though not always.

Makita always seemed to be a lighter weight tool, not really suited for long, hard use. Considerably cheaper, but without the power or life span.

At the same time, however, I have borrowed several Makita tools in the past few years for short term use and was impressed - Makita has made long strides in producing a quality tool. Unfortunately, they have also increased the price to around the equivalent of the top tools.

Mike on June 08, 2012:

Have you used all the tools your recommending? I have both a Milwaukee and a makita impact set, and the makita has both outlived and outperformed the Milwaukee by far

Dan Harmon (author) from Boise, Idaho on May 18, 2012:

Niall, you make me jealous, going tool shopping for more than just one or two items. It's been a long time since I did that.

Niall on May 17, 2012:

Thank you very much for this! I am in high school and will be starting a CO-OP program next year to become an electrician. I already have many of the basic tools (most aren't that great though) plus a drill/impact and clamp meter, but this definitely helped! Looks like I'll be in for some tool shopping, one of my faourite activities!

Dan Harmon (author) from Boise, Idaho on April 21, 2012:

aman, I'm afraid you've come to the wrong place. An electrician and a lineman carry very different tools for very different purposes and I know next to nothing about a lineman's tool set. Sorry.

aman on April 21, 2012:

hi , am student in electrical technology and am doing a project on linemans stc. i am trying to finf out the correct tools and there usagae for a lineworker in his ever day usage in pole work.

can any1 have a say on this thanks.

aman

Dan Harmon (author) from Boise, Idaho on December 11, 2011:

Oh I can believe it! In our case by the time we find the defective fixtures it is to the point that they have to be installed NOW. Which means we have to fix them at our expense. We'll get ballasts for free, but all labor and small parts are ours to cover.

Manufacturers know we can't wait - given that, why try for a high rate of "perfects"? It doesn't cost them anything to put out crappy work - engineers and architects choose the fixture based on appearance and price, and we fix them for free.

Wesman Todd Shaw from Kaufman, Texas on December 11, 2011:

I'd worked for years for a contractor who'd decided to sell Nordyne equipment...Westinghouse, Tappan, and their other brands.

The guy...the contractor that I worked for...was the SINGLE most HONEST and ...truly, one of the most mechanically inclined individuals that I'd ever met anywhere.

The systems that he'd sold...were poor to awful from the factory, and though he was in a position to where he could retire at any time...that shit equipment cost him some "face" or reputation.

So he stopped selling Nordyne...and started selling Rheem. Now...Rheem is GOOD equipment by and large - it's the equal of Trane, Lennox, or Carrier/Bryant...at least it is in my personal experience.

But there was one customer that had bout an expensive 14 SEER system...and after MANY hours of warranty work in which I'd looked over every single last possible thing that someone usually thinks of....I found..about three or four..can't recall - TINY leaks on the larger of the two copper lines inside the condenser.

Those super small refrigerant leaks were so tiny that no refrigerant oil could be seen, and they were so small that the brand new $300 dollar digital leak detector - an instrument able to detect 1/4 pound refrigerant leak per year...ostensibly...didn't sniff them. It could only "find" them within six to eight inches of space that had copper tubing going everywhere.

I wound up finding the leaks from pressurizing the system past running capacity...with my hands from touch.

That shit shouldn't have ever passed quality control...but it did, and it was an above minimum standards condenser from one of the best manufacturers.

Negative story...but all true

Dan Harmon (author) from Boise, Idaho on December 11, 2011:

Don't get me started on manufacturer defects; it is a rare school or store that we build that doesn't have at least 10% of the new light fixtures defective in one way or another. Wired wrong, defective ballasts, broken or missing parts; it's always something.

It's why I recommend only top quality tools for tradesmen - you can generally trust them and many carry a lifetime guarantee.

Wesman Todd Shaw from Kaufman, Texas on December 11, 2011:

You only ever need a recovery machine if there is gas in a system, and you're replacing either the compressor, filter, or planning to REPAIR a leak - then you need to use a vacuum pump to not only remove the oxygen or atmospheric "air" from the system....but holding the vacuum or negative pressure is a second or third confirmation that a leak is actually fixed.

The thing is....most a/c or heat pump refrigerant leaks occur in the very freaking thin copper tubing of the indoor coil - and nobody....is going to repair those leaks, as they are often microscopic...or exceedingly difficult to find.

Also.....were someone to take the time to repair an indoor coil refrigerant leak - that in and of itself is not a profitable thing for the tech or contractor - but it's not going to be cost effective for you either.

Then...the nature of those kinds of leaks, formed from vibration and rust...pretty much determine that another one will soon follow - and so it's never ending misery for all persons involved to even mess with that.

Much better to have a leak develop at the condenser!!!!

Or to simply pay someone to charge the thing....until the leak becomes big enough that it's more cost effective for you to just replace either the indoor coil, the whole air handler/furnace - or to bite a bullet and get a new system.

It's a bad deal for everyone, Sir, and some of the manufacturers in the US have slipped on quality to very bad levels of late - and the whole situation ...mostly just makes your contractor look bad, even should it be the poor equipment that he'd had the confidence in to sell you.

Dan Harmon (author) from Boise, Idaho on December 11, 2011:

I'm sure you could - I've watched and it just isn't that complex a job. It does, however, require specialized tools and equipment that don't have a lot of use elsewhere - it isn't reasonable to buy these things for just one job.

As you say, a pyrometer of some kind, gauges and gas to start with. If you need to re-fill, there is probably a leak that needs fixed and now don't you need an evacuation system to be legal? Cheaper to just call a serviceman for this kind of thing.

Wesman Todd Shaw from Kaufman, Texas on December 11, 2011:

If you ever had gauges and the gas...and something to measure temperature with that is faster than an old fashioned thermometer - I could walk you through charging your heat pump.

It gets profoundly more difficult though, when someone is trying to charge one in heating mode - that's hard to get done.

Dan Harmon (author) from Boise, Idaho on December 09, 2011:

First, be aware that there is a difference between having a rubber-cushioned handle and being insulated. Most of the rubber coated handles are not listed by the manufacturer as insulated against high voltage - the rubber is for comfort only, and is well worth the extra cost. It also gives extra grip - screwdrivers can be turned much harder with a rubber handle than a plastic one for instance.

True insulated tools are quite a bit more expensive and seldom necessary. My own tool kit has all rubber handles, but zero insulated ones. The rubber, or even a plastic handle, will insulate from electric voltages well enough in the voltage range I deal with, which is typically up to 480 volts.

Work with screwdrivers, pliers or wire strippers all day long, though, and that comfort provided by the rubber handle quickly becomes worth twice what it cost.

Daniel on December 09, 2011:

Hey . I see alot of insulated tool sets. They are expensive. What is the need ?

Dan Harmon (author) from Boise, Idaho on November 05, 2011:

You may be right about HVAC hubs. I will work on my heat pump up to the point that I have to deal with Freon. I just don't have the knowledge or tools for that, and I doubt that many do.

I'm a little more fortunate in that everyone has a screwdriver and can change a light switch or something with just a little help, and I can provide that.

Wesman Todd Shaw from Kaufman, Texas on November 05, 2011:

You've sort of reminded me here about a hub I intend to write. I wrote one about "the worst service call that I ever went on." - well, I've got another installment for that.

I've been disappointed with most of my hvac hubs - I've about determined that folks aren't too interested in reading about that stuff - I think most just hit the phone book, or call the people that they already know when there is a problem!

Dan Harmon (author) from Boise, Idaho on November 05, 2011:

While I can enjoy the challenge of a service call (usually something has gone wrong somewhere and it's often not electrical at all), not in residential. I'm not much of a rafter rat and don't enjoy crawling around the crawl spaces through rats, snakes and spiders, either.

No, give me a nice clean, warm commercial job. I'll put up with the craziness of customers. I once had a woman and her little girl sit down to rest on the lift I was working from 20 feet over her head (she jumped up pretty quick when the lift moved a couple of inches!) but it's better than the snakes.

Wesman Todd Shaw from Kaufman, Texas on November 05, 2011:

Yeah - that's my thoughts on wiring homes, hanging lights, and slinging plugs and switches - it's sort of mindless busy work that gets you some exercise in.

Of course my dad and his two brothers and brother in law (and then - all of their sons except me and my brother) - are pretty much all with Master's licenses.

It pissed my Dad off the way they'd changed the laws here in Texas - making it easier to get that Master's license.

I like electrical troubleshooting in residential air conditioning - I'm not so talented at it that I can do much more than light commercial. I really like that stuff because you are constantly moving - and can wind up going to five to ten different service calls on a good day.

Dan Harmon (author) from Boise, Idaho on November 05, 2011:

Really? I typically enjoy the work. I don't, however, wire homes - all of my work is either commercial or industrial and it is a lot more varied and interesting than residential work. Always something new and different, whereas when you've done one home you've pretty much done them all.

Wesman Todd Shaw from Kaufman, Texas on November 05, 2011:

I used to do that job. I pretty much hated it.

My brother and I ...are the only males in the Shaw family that aren't electricians - half the in laws are electricians as well.

My Dad....likes nothing better than drilling holes and pulling wire in a home being built. I can't figure out why I dislike electrical work so much...when I actually enjoy running hvac service calls.

Dan Harmon (author) from Boise, Idaho on September 02, 2011:

In my (very) limited in industrial maintenance the company has provided virtually all the tools. I would suggest saving up for when you graduate and get a job so that you can, if necessary, purchase the tools you will need. It could vary considerably from company to company as the actual maintenance could be very different. One might include installing a good deal of new equipment with all new conduit and wire while the next could be full of high tech electronics and require a laptop as a primary instrument.

Just one additional thought on the field; if you are interested in one day owning your own company it will be very unlikely in the maintenance field. Construction and installation could well turn into a private business one day. Highly risky (most small businesses fail) but it can be highly rewarding as well.

Good luck!

Daniel on September 01, 2011:

Thats pretty much in line with what i have been thinking. Thanks again for the dialogue. I do have a family and was already leaning towards manufacturing maintenance. What kind of tools do you believe to be vital for someone starting in that field?

Dan Harmon (author) from Boise, Idaho on September 01, 2011:

I'm assuming your degree will put you in the field with tools in your hands and not behind a desk designing either a construction job or maintenance program.

Given that, construction will put you all over the place and maybe all over the country. Every few months you will have a new job to work on with much different challenges. You may well be unemployed part of the time while between jobs.

Maintenance, even at a large facility, will soon become the same thing day after day. You will be more stable in both employment and location (I spent 20 years doing most of the electrical maintenance, among other things, at one location). Pay per hour is probably better in construction, but maintenance probably won't see the common layoffs.

They are two very different fields, with very different pros and cons. Either one can offer advancement into supervisory and/or management. Both have there individual challenges.

If you have a family the maintenance may well be better because it is more stable, but the pay probably isn't as good. It's a tough choice. I've found I like construction far better, but being laid off periodically hurts.

Daniel on August 31, 2011:

Thanks for the feedback.Im in technical school now. In 9months I will graduate with a degree in electrical maintenance and construction technology. The way I see it I have two possible paths. Construction / Installation and manufacturing maintenance. What direction would you recommend?

Dan Harmon (author) from Boise, Idaho on August 27, 2011:

I am not familiar with that model. I would have to say, however, that 12V just isn't going to be enough. Even if the drill is designed to produce enough high torque at low speed to drill large holes the battery simply won't last at that low a voltage.

I commonly drill 1"+ holes in both wood and steel with my cordless set, and a 12V unit just isn't going to be able to do that with any consistency. Even if it could drill that size hole through a 2X4 or a panel can it won't drill very many and the drill probably won't last long either.

On the other hand, it would probably do fine if all you are doing is driving screws. An impact driver with 18V will drive many, many screws before needing charged and it doesn't overwork the driver at all even with large screws into 2" lumber - I don't see why a lower voltage wouldn't work nearly as well.

If this is what you're doing, check out impact drivers. I've just added a link in the drill section of this hub to a hub on impact drivers - you might check it out. You can buy smaller drill bits to drill wood that will fit into the driver, and I have used a spade bit up to around an inch with an impact driver, but wouldn't want to do it on a frequent basis.

daniel on August 27, 2011:

Wilderness are you familiar with the Milwaukee M 12compact line? Is 12 volts enough?

Dan Harmon (author) from Boise, Idaho on September 20, 2010:

It's always a question for the apprentice - just what to buy and what is necessary vs what is nice to have. Thanks for the comment.

Dan - Gold Coast Electrician on September 19, 2010:

Great review of the tools needed. Nice work!

Dan Harmon (author) from Boise, Idaho on August 25, 2010:

Thank you for the compliment. If you are interested I have written several hubs on the use of hand benders, as well as one on the non-contact voltage tester.

SteveoMc from Pacific NorthWest on August 24, 2010:

Great information, I am pretty much a handiman and I was very interested in the tools...I love them and have most of the ones you talked about. Would even like a little more information about how to use some of them. Great JOB!

Dan Harmon (author) from Boise, Idaho on August 23, 2010:

Unfortunately no award, but thanks for the comment. Yes, about the same time on HP - I hope you're enjoying it as much as I am.

Denise Handlon from North Carolina on August 23, 2010:

Wow, this could have earned you a hubnugget award (did it?) Very cool. You've been a member here for about as long as I have...nice meeting up with you. :)

how to become an electrician apprentice

Source: https://dengarden.com/home-improvement/Recommended-electrician-hand-tools-for-the-apprentice-becoming-an-electrician

Posted by: waferreatim.blogspot.com

0 Response to "how to become an electrician apprentice"

Post a Comment